The Robert M. Kerr Food and Agricultural Products Center

By Lora Buntin

Spring 2022

A simple Google search for “the Robert M. Kerr Food and Agricultural Products Center” reveals nearly 19,000 news articles. Nineteen. Thousand. I could write a page a day during this semester and would still never be able to cover all of the things and people that make the center great. Its people simply have done so much and are so involved with the community and the state, and the impact that the center has had and will continue to have is immeasurable. That being said, I’ll do my best to give you the highlights so that you may come to appreciate its work as much as I do.

During the 1980s Oklahoman farmers faced a huge problem within the agriculture industry. Oklahoma has always been well renowned for its agricultural industry and its commodity production, such as raw crops and livestock. During the ’80s and early ’90s, Oklahoma’s agricultural economy was facing a stand-still. Senator Robert M. Kerr took notice of this issue and sent a letter to Oklahoma Legislature in the spring of 1991. Senator Kerr emphasized that “Oklahoma was processing significantly less than 10 percent of what it was producing, losing value-added jobs and manufacturing-based profit margins and taxes from processing and finishing”( 1997-2017 A look into the first 20 years). He proposed that a value-added manufacturing facility be created in order to convert these Oklahoma commodities into “value-added” products in order to expand the horizons of Oklahoma’s ag economy. He succeeded, and the Robert M. Kerr Food and Agricultural Products Center (FAPC) was completed in November 1996 and opened its doors in January 1997. The center was not built in vain, as it has had a large impact on Oklahoma’s agricultural economy as it was set out to do. It has helped businesses, small and big alike, flourish and improve throughout the years. Not only does it have an industry-wide impact, but it also has deep personal connections to those who have worked with the faculty.

It was originally named the Oklahoma Food and Agricultural Products Research and Technology Center, but its name was changed in 2007 in honor of the late senator’s role in its conception and development. He wasn’t the only person who worked hard for FAPC’s creation, but he definitely served as a spearhead for its development. The road to success wasn’t an easy one either. The proposal for the Robert M. Kerr Food and Agricultural Products Center went through many revisions before it was finally completed on November 29th, 1989, and passed unanimously through Oklahoma Legislative in January of 1990.

The whole original goal of the FAPC’s creation was to turn Oklahoma’s raw commodities into value-added goods, but what exactly does “value-added” mean? The U.S. Department of Agriculture defines value-added products as follows: “As a result of the change in physical state or the manner in which the agricultural commodity or product is produced and segregated, the customer base for the commodity or product is expanded and a greater portion of revenue derived from the marketing, processing or physical segregation is made available to the producer of the commodity or product.” In simple terms, it essentially means that you’ve taken a raw agricultural commodity, such as wheat, and turned it into a more valuable and consumer-friendly product, such as flour or even bread. Or as Jake Nelson, FAPC’s previous Meat Processing Specialist explained in a personal interview, “We use that term “value-added” to promote more of the conversion of agricultural commodities into something useful for people. Most people can’t take a slaughter steer, or a bushel of wheat, or a bushel of whatever, these raw commodities, people just can’t use that. You’ve gotta make it into something useful.”

The Robert M. Kerr Food and Agricultural Products Center has not only knowledgeable and helpful faculty and staff but also board members that represent all aspects of the agricultural industry. The Industry Advisory Committee was created in order to “have a consistent and broadly based oversight council that represented very specific sectors of the food and agribusiness industries in Oklahoma”. The committee consists of 15 industry leaders from all different aspects of the agriculture industry. The first Industry Advisory Committee meeting took place at FAPC in May of 1997. Gary Crane, owner of Ralph’s Packing Company in Perkins, Oklahoma, was one of those original members before he retired in 2017 after serving for nearly 20 years. His daughter, Erica Hering took his place on the committee in October of 2016, and has been very actively involved ever since, currently serving as Chair of the committee. I was fortunate enough to conduct a personal interview with Miss Hering to learn about how the Food and Agricultural Products Center has helped and positively impacted small Oklahoma businesses such as Ralph’s Packing. Possibly the strongest connection that Ralph’s Packing currently has with FAPC is with FAPC’s pilot processing plant. “We work really close with the pilot plant and the meat lab. Any time they’re doing harvesting of animals they need an outlet for the meat that comes out.” So how does Ralph’s utilize that meat? Ralph’s contributes to the Beef for Backpacks Program, part of the Regional Food Bank of Oklahoma, which focuses on making sure that no kid goes hungry on the weekends and school holidays, as some kids rely on the public school system for a large portion of their meals. Ralph’s uses the meat from FAPC’s pilot plant to help make snack sticks that they donate to the program. According to Miss Hering, FAPC helped establish the connection between Ralph’s and the food bank, saying “They were the go-between when we set up our relationship with the Regional Food Bank of Oklahoma and started the program for the Beef for Backpacks and Pork for Pack Program.”

They were the go-between when we set up our relationship with the Regional Food Bank of Oklahoma and started the program for the Beef for Backpacks and Pork for Pack Program.

Ms. Erica Hering,

Ralph’s Packing Company

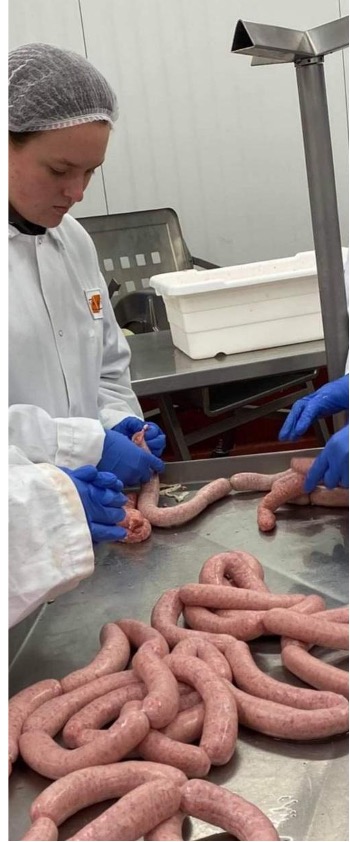

The meat that isn’t contributed to Ralph’s packing is used in a variety of different ways at FAPC. Carcasses are used for practice judging for Oklahoma State University’s Meat Judging Team, as they get hands-on experiences of what qualities to look for in a carcass for judging purposes. Not very long after I started working for the Animal Science program I helped graduate students package ground beef into one- pound chubs to donate to a local food bank called Our Daily Bread. I don’t remember the exact amount of meat, but it was well over a hundred pounds at least. Some of the meat is made into specialty smoked sausages, bacon, and such, as I experienced in an Animal Science Honors class I took last semester titled Retail/Food Service Meat Value: Honors. It was a very hands-on class, nearly every week including students helping to create or witnessing the creation of some kind of meat product. My favorite thing that we made was a German-style smoked sausage, as running the sausage-stuffing machine was a lot of fun and the sausages turned out really good.

Growing up helping my dad process deer and butcher steers, and making lots of homemade bratwurst (my dad has been a butcher since he was in 8th grade) the process was nothing new to me, but the equipment was a much larger scale than I was used to, which I found really interesting. I knew that I was raised a little differently than most people my age, (I doubt a lot of people go home to help their dad make hotdogs on the weekends), but I didn’t realize how little people my age know about the meat industry or how processing happens. I don’t think a lot of people spend much time thinking about where the hamburger that they are buying at Walmart comes from. Sure it comes from cattle, but there are so many steps involved, like slaughter and breaking down the carcass and deboning and grinding and packaging.

I think that is one really important aspect of FAPC, its ability to teach future generations. Not only does its work help entrepreneurs that already have a general idea of or an area of expertise in the food industry, but it also has the potential to teach students who have very limited knowledge of how the food industry works. I feel like in general, my generation sometimes takes for granted where their food comes from. Everything is so easy and accessible and prepackaged, and if you didn’t grow up in an environment where you were exposed to the nitty-gritty of food production, you don’t think about the bigger picture. With its location, FAPC is in the perfect position to expose students to new ideas and information. Not everyone is going to want to be a Food Science major like me or find the process as interesting, but I think it’s still important that they are given some background information and have a general understanding of where their food really comes from. Everyone has to eat. Therefore, it’s important that we continue to learn and develop technologies in the food industry.

FAPC doesn’t work alone in its mission to positively impact Oklahoma’s agricultural economy. It cooperates with the Made In Oklahoma Coalition (MIO) which works to promote Oklahoma brands and businesses also in order to support the state’s economy. The MIO website lists FAPC as an associate member of the coalition. According to MIO, “FAPC has assisted more than 1,000 Oklahoma clients through 3,000 technical and business projects.”

So what are some of those projects? FAPC’s website, food.okstate.edu lists the general focus areas of their available programs, including “Facilities and Equipment for Food processing, Food Safety, Quality Management and Sanitation, Food Packaging and Labeling” as well as many others. You can get more detailed information about some of those programs under the Training and Services tab. There they have details about the 50+ education/training events held annually. Some of their seminars do require a cost for attendance, but they have quite a few seminars free to the public as well.

The “Homemade Food Freedom Workshop” is one such event that the public can freely enjoy. This is an example of one such workshop that an entrepreneur could attend to help them get a feel for the personal business aspect of the food industry and see if they think it is really for them, before they make any kind of big financial investment. Food safety is a growing concern within the industry, and the FAPC has taken notice. As Miss Hering mentioned, “ (The food safety portion) is one of the newer programs at FAPC that has been slowly gaining interest for the past 20 years or so, (but has really gained interest) in the last 8 to 10 years. When you talk about food safety you’re not just talking about vegetables or condiments but it really goes all the way down to the initial producer.” She went on to explain why food safety is so important, particularly for business owners and producers such as Ralph’s. “So many of your large grocery store chains require you as a food producer to have some kind of food safety auditing scheme. It’s still a relatively new idea for certain food processors, and the programs are still changing. There’s been somebody on staff at FAPC that can go out and help food businesses across the state to prepare their facilities and their employees for these food safety audits. I’d say that is probably the biggest help that FAPC has been for us in recent years, is getting us prepared for all of these food audits.”

The Robert M. Kerr Food and Agricultural Products center obviously has a positive impact on business owners and entrepreneurs, but what impact does it have on its staff and faculty? I spoke with Jake Nelson, who served 24 years at FAPC as Facilities Manager and Meat Processing Specialist. He was one of the first employees hired when the center opened, so if anyone had a good idea of what working there is like, I knew he would be one of them. After all, he carried the first box of meat into the center. “ I moved the first box of meat into the FAPC, I remember it was a box of hams for another (graduate) student’s project.” When I asked him why he stayed at FAPC for so long he replied, “Because I had a role, I was in somewhat of a leadership role for daily activities. It was fun because there was an energy about it, there was attention and focus and people wanted to be in there doing things. It was a new project every month, and I guess I stayed so long because nothing ran me off. It was a lot of fun projects, it was enjoyable.” The employees at FAPC definitely faced a learning curve in the beginning, though. As Mr. Nelson said, “The construction folks walked away, said here’s the keys, have at it. We spent another year installing very specific utilities for equipment, thinking about flow, thinking about room function, and trying to forecast and predict what the center was going to be, what it should be, what it’s expected to be. That was all very infant. We felt like infants and toddlers kinda just crawling around trying to find our way. And then it all started growing quickly….you just started finding your way.”

Because I had a role, I was in somewhat of a leadership role for daily activities. It was fun because there was an energy about it, there was attention and focus and people wanted to be in there doing things.

Jake Nelson, Facilities Manager and Meat Processing Specialist

Not only do full-time staff enjoy working at FAPC, but student workers have a good time as well. Their time spent learning and working hands-on within the facility makes a difference in their lives, as Keith Schneberger of Keith’s Butcher Shop explained in a interview posted on FAPC’s Facebook. Mr. Schneburger worked at FAPC as a student at OSU and opened his own butcher shop a mere 2 years after his graduation. “I picked up all the skills I needed to open a butcher shop by working at FAPC”. I think I learned more at FAPC than I did in the classroom. I knew I wanted to come back home after college graduation and there was business to be had in the food industry.”

A more recent graduate of OSU also had good things to say about their time at FAPC as a student. Courtney Elroy graduated from OSU with a degree in Foodscience in 2018. In an article in the Marlow Review she tells how staff at FAPC and their programs and classes prepared her with the skills she needed for her job at J-M Farms, which happens to be one of the companies that FAPC is closely associated with. “Getting to work inside … FAPC really helped me understand the industry,” Elroy said. “All of the different things they offer teach students valuable lessons.” Miss Elroy worked with the Department of Animal and Food Sciences Research Scholars Program during her freshman year, conducting research in FAPC. Staff played an important role as well, as the article goes on to read “Dr. Ravi Jadeja, an assistant professor and food safety specialist in the Robert M. Kerr Food & Agricultural Products Center (FAPC), also played a big role in Elroy’s journey at OSU.” J-M is closely connected with FAPC because Virgil Jurgensmeyer, the chief executive officer of J-M Farms, was one of the original members of the Industry Advisory Committee of FAPC. He also helped to start the food safety program.

My first personal encounter with the Robert M. Kerr Food and Agricultural Products Center was “love at first sight”. I grew up in the little town of Glencoe OK, which is about 20 minutes away from Stillwater. I was given the opportunity to attend vo-tech classes at Meridian Technology Center during my junior and senior years, since Glencoe is one of the schools that they work with. I’ve always been passionate about the food industry, so naturally I joined the Culinary Arts program. One warm spring day in 2020, my instructor took the whole culinary class to FAPC for a tour. I’d never heard of FAPC before, never even knew it existed until we hopped off the bus and walked through those big glass doors. I was amazed by the vastness of the building, how much room they had just for research, how many different departments they had, and all of the different projects and possibilities that lie ahead. That day I walked into a building full of people that were passionate about the same things I am, which means a LOT to a 16-year-old who is just starting to find their way.

In January of 2021 Jake Nelson, who served as the Meat Processing Specialist and a Facilities Manager for 24 years, began working at Ralph’s Packing, where my dad has been working for many years. My dad and Mr. Nelson hit it off really well and soon became good friends. My dad introduced us, and then we hit it off too. So well, in fact, that when he heard that I didn’t have a summer job (I had just graduated high school), he recommended that I start working for the Animal Science Department at OSU. Having worked at FAPC since the doors first opened, Nelson is well-known within the Animal and Food Sciences community. With his connections, he convinced Dr. Mafi of the Animal Science Department to interview me. I’ve been a student worker under Dr. Mafi for almost a year now, since last June. I technically work for the Animal Science Department, but it is so intertwined with and connected to FAPC that I get to do quite a bit of work over there as well.

My main job is to help the graduate students with various research projects and experiments, and a lot of the time we use some of FAPC’s facilities for those projects. Since Jake Nelson left, there hadn’t been as much going on with the processing plant as of late, until the new Processing Plant Manager Joel Jackson was hired in December of 2021. Since then, the slaughter plant has become busier and operational again. With my dad’s meat processing background and thus my involvement since being a child, I was thrilled when they asked if I’d like to help them process over at FAPC’s pilot processing plant. It’s hard work but it’s very rewarding. The people and staff at FAPC are masters of their trade, and they are welcoming and inclusive to everyone. One thing that I really like about working with Mr. Jackson is that after we are done processing we have a group meeting to discuss any issues that we had and how we can do better, that way can take any suggestions and comments from each other and continually improve the craft.

So has FAPC met its goals set forth by its founders? I believe that it has. It is without a doubt, adding value to Oklahoma. Not only through adding value to Oklahoma’s ag industry, as it was originally created to do, but through the enrichment it gives its business partners, beginning entrepreneurs, its faculty, students, and every consumer that enjoys safe food products, and products made by Oklahoma businesses. I think that it will only to continue to grow its programs and business partners, hence expanding its impact in the food industry.

Works Cited

“2015 Robert M. Kerr – Western Oklahoma State College: Altus, OK.” Pioneer News Blog, Western Oklahoma State College, https://www.wosc.edu/index.php?page=2015-robert-m-kerr. Accessed 12 April 2022

“2021 Virtual Research Symposium”. YouTube, uploaded by okstatefapc, 8 April 2021, https://www.youtube.com/watch?v=toO73Ocwp4Y Accessed 21 April 2022

“20 Years of Made In Oklahoma Food Innovation”. YouTube, uploaded by okstatefapc, 26 May 2017, https://www.youtube.com/watch?v=yLvk-3bs2U4 Accessed 21 April 2022

Escoubas, Roy. 1997-2017 A look into the first 20 years. Oklahoma State University, 2016. https://issuu.com/brandosu/docs/fapc_history_book, Accessed 10 April 2022

“FAPC Virtual Tour”. YouTube, uploaded by okstatefapc, 6 April 2021, https://www.youtube.com/watch?v=VJR0saxbVoo Accessed 21 April 2022

Hering, Erica. “Meet Erica Hering: Secretary of the FAPC Industry Advisory Committee.” The Food Files. By the Robert M. Kerr Food and Agricultural Products Center, 7 May 2020, https://www.podbean.com/media/share/pb-tey3u-dbb4c5?utm_campaign=u_share_ep&utm_medium=dlink&utm_source=u_share Accessed 14 March 2022

Hering, Erica. Personal Interview. 15 Apr. 2022

Hollansworth, Kirsten. “Rising in Research: FAPC hosts annual research symposium”. 16 March 2022. https://news.okstate.edu/articles/agriculture/2022/research-symposium.html

Keith, Schneberger. Personal Interview. 13 Apr. 2022.

MarlowReview. “A Taste for Food Science.” Marlow Review, A Proud Heritage… A Bright Future, The Marlow Review, 13 Sept. 2018, https://www.marlowreview.com/articles/6340/view.

Nelson, Jake. Personal Interview. 15 Apr. 2022

Oklahoma Farm Bureau Foundation for Agriculture. “Beef for Backpacks and Pork for Packs.” Oklahoma Farm Bureau Foundation for Agriculture, 2022, https://okfbfoundationforagriculture.org/beef-for-backpacks/. Accessed 23 April 2022

@Robert M. Kerr Food and Agricultural Products Center. “Keith Schneberger graduated from Oklahoma State University with a bachelor’s degree in animal science in 2006. Throughout college (2002-2006), he worked as a student employee at FAPC and was a member of the Oklahoma State Meat Judging Team. After graduation he built and opened Keith’s Butcher Shop, located in Burns Flat, Oklahoma, in July 2008. Keith specializes in custom processing as well as a retail market. Keith and his brother Curtis also own and operate Keith’s Meat Market in Elk City, Oklahoma. “I picked up all the skills I needed to open a butcher shop by working at FAPC,” Schneberger said. “I think I learned more at FAPC than I did in the classroom. I knew I wanted to come back home after college graduation and there was business to be had in the food industry. My goal is to develop a good quality product while making a good living doing it.” Facebook, 25 July 2020, https://www.facebook.com/page/75318990801/search/?q=Keiths%20butcher%20shop

United States Congress House Committee on Agriculture. Formulation of the 2002 Farm Bill. U.S. Government Printing Office, 2001. https://www.google.com/books/edition/Formulation_of_the_2002_Farm_Bill/o2b0LXLD7OYChl=en&gbpv=1&dq=%22Oklahoma+Food+and+Agricultural+Products+Research+and+Technology+Center%22&pg=PA1567&printsec=frontcover Accessed 20 March 2022

U.S. Department of Agriculture, Rural Business Development. “USDA Value-Added Ag Definition.” Agricultural Marketing Resource Center, 2022, https://www.agmrc.org/business-development/valueadded-agriculture/articles/usda-value-added-ag-definition. Accessed 23 April 2022